In today's modern logistics world, optimizing storage space combined with advanced equipment is the key to success. Smart racking systems and high-quality forklifts are playing an increasingly vital role. Drive-in racking is a breakthrough solution that enables business to store goods at high density, saving both space and costs. In this article, Nhat Lo Phat 168 will walk you through what Drive-in racking is, its advantages and limitations and most importantly, which forklifts are best suited for Drive-in racks.

What is a Drive-in racking system?

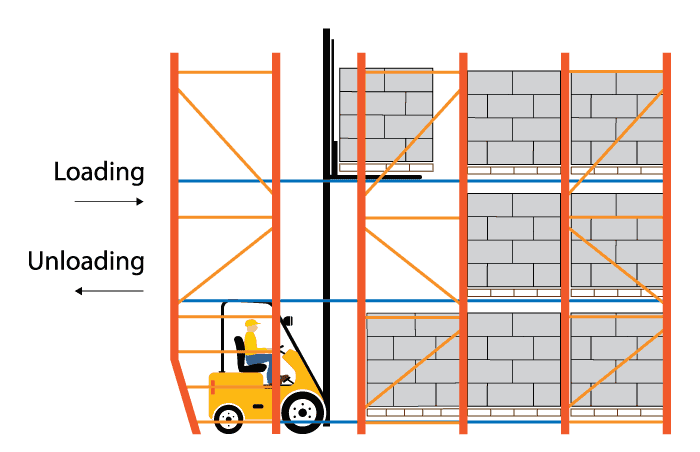

A drive-in rack is a storage system designed for forklifts to drive directly into the rack lanes to load and unload goods, eliminating the need for multiple aisles between racks. This allows businesses to increase storage density by up to 80% compared to conventional racking systems.

Instead of using horizontal beams like standard racks, drive-in racking uses support rails, enabling forklift to move straight into the lane and store multiple pallets of goods in the same row.

The system operates on either the LIFO (Last in, first out) principle for Drive-in rack (single-entry) or FIFO (First in first out) for Drive-through racks (double-entry).

>> Reference: What is Double Deep racking? Which forklifts are suitable for Double Deep racks?

Advantages and disadvantages of drive-in racking

Advantages:

- Optimized storage space: Drive-in racking reduces aisles between racks, maximizing warehouse capacity, ideal for warehouses with limited floor area but high inventory volume.

- High storage density: Can store from 10 to 12 pallets deep per lane.

- Cost effective investment: Compared to automated systems like Shuttle racks, Drive-in racking is more affordable while still delivering high efficiency.

- Easy installation and expansion: Modular structure allows flexible adjustment to warehouse needs.

Disadvantages:

- Difficult access to inner pallets: Due to the LIFO principle, retrieving pallets stored deep inside is consuming more time.

- Product requirements: Not all types of goods are suitable for this type of racking. Stored products should be uniform and durable for longer storage periods.

- High collision risk: Forklifts must drive directly into the racks, increasing the risk of collisions and rack damage.

Which facilities are suitable for drive-in racking?

Although drive-in racking offers outstanding advantages, optimizing warehouse space by up to 80%, but businesses need to certain conditions to ensure compatibility:

- Homogeneous goods: Products with the same dimensions, pallet load from 500kg to 1000kg.

- Warehouse dimensions: Best suited for facilities with limited floor space but high ceilings, prioritizing depth storage.

- Storage priority over throughput: More suitable when maximizing storage capacity is more important than fast retrieval.

Drive-in racks are widely used in manufacturing, distribution, dry food storage, pharmaceuticals, etc.

Forklift suitable for drive-in racking

Due to its unique structure, drive in racking requires forklifts that are specifically designed for this application. A suitable forklift must be compact enough to drive inside the racking lanes, capable of lifting loads to significant heights while maintaining stability and safety. For these requirements, the following forklift lines are optimal choices for businesses:

Hyundai electric counterbalance forklifts:

Hyundai offer a wide range of compact electric counterbalance forklifts with a tight turning radius, making it easy to maneuver in and out of drive in racks without collision risks.

Accurate steering capability, displayed directly on the screen, helps the forklift move more sagely in narrow spaces.

Smooth operation, no vibration when placing loads at high positions.

Lithium-ion battery option support continuous, uninterrupted operation.

Refer to Hyundai’s notable electric forklift series: BE-X, B-9F, B-9U...

Crown electric counterbalance forklifts

Crown forklifts from the USA have consistently ranked among the TOP 5 best forklift brands worldwide. Their models are well known for advanced technology, solid, durable design and long-lasting performance.

The most notable Crown electirc counterbalance forklift series are the SC series and FC series, both ideal for narrow spaces. Crown electric forklifts deliver outstanding performance in every aspect. Crown's intrinsic stability system ensures absolute safety and reliability.

The dual-drive system and steer axle design allow the FC series to rotate 360° within the aisle without affecting surrounding rack structure. A wide field of vision is another crucial advantage when operating forklifts in drive in racking.

In addition, Crown forklifts are equipped thiwh advanced safety systems, refined and durable design.

>> Learn more here: Crown FB series

Hyundai Reachtruck BR-X model

Hyundai BR-X and BR-9 series stand-on reach trucks are an optimal choice for drive in racking. With a compact design width of about 1-1.3m, turning radius of 1.65-1.84m, they can easily maneuver in tight spaces.

They provide excellent visibility, lifting height up to 7.5m, anti-vibration and shock absorption design, plus multiple safety systems such as speed limiter and OPSS, etc.

Crown ESR sit-down reachtruck

The Crown ESR model is a sit-down reach truck designed with a moving mast system. Instead of only the forks moving forward, the entire mast shifts forward to retrieve pallets, giving operators a better line of sight when working with deep racking.

Like Hyundai, this model is compact and integrates advanced technologies such as Xpress Lower to increase fork-lowering speed, which improves productivity.

Another standout feature is auto height select, perfect for high-bay warehouses. The forks automatically stop at pre-programmed rack heights with just the press of a button.

For more details, check here: ESR Crown.

Watch the video of Crown FC operating in a drive-in racking system here:

Where to buy reliable forklifts for drive in racking?

Choosing the right forklift and racking system is just the first step, the rest depends on partnering with a trusted supplier. Nhat Lo Phast 168 is proud to be the exclusive distributor of Hyundai forklifts and the official Crown dealer in Vietnam. With 24 years of experience, we have achieved great success and earned the trust of customers across the country.

NLP168 guarantees:

- 100% genuine products, directly imported from the USA and South Korea.

- Dedicated after-sales service and maintenance, ensuring your forklifts always operate safely and reliably.

- 24/7 customer support with a knowledgeable and professional team.

Contact us today for detailed consultation on the most suitable forklifts for your Drive-In racking system!

- Nhat Lo Phat 168

- North Vietnam: 093 208 1688

- South Vietnam: 090 345 1688

- Email: duynl@1688.com.vn

- Instagram: https://www.instagram.com/nhat_lo_phat_168/

- Facebook: https://www.facebook.com/Nhat-Lo-Phat-168-Leading-Total-Forklift-Solution-Supplier-103205604743397

- Youtube: https://www.youtube.com/@nhatlophat1688